Ty-Flot. Built on Trust.

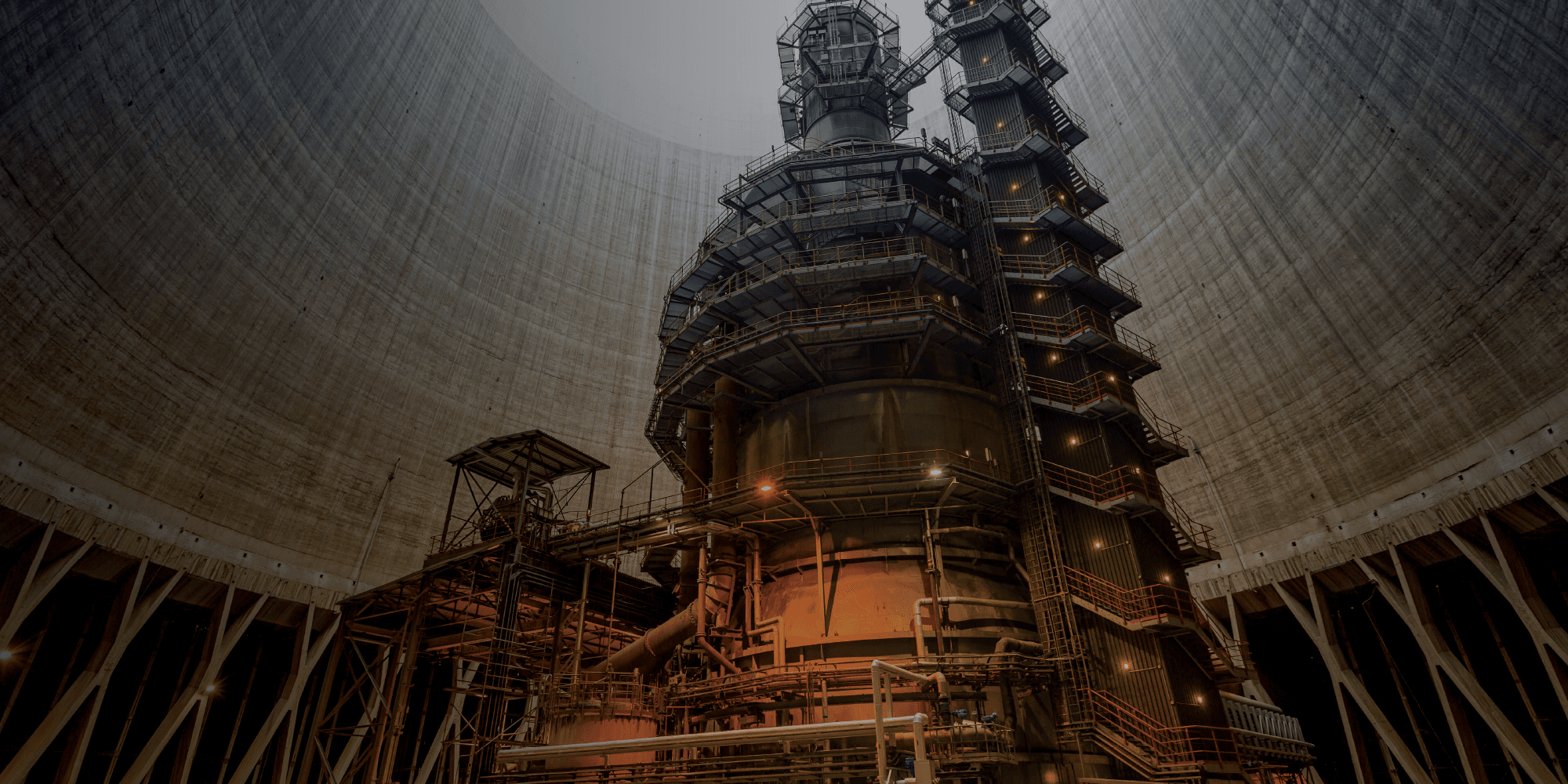

Ty-Flot’s dedication to the global nuclear industry is rooted in providing best-in class Foreign Material Exclusion solutions for ultimate system protection. With an ever-expanding portfolio, industry diversification, and a reputation built on trusted expertise, Ty-Flot ensures safe and efficient operations, enabling our partners to prioritize their critical objectives. As a proud member of the Guardian family, Ty-Flot remains the go-to choice for debris contamination prevention, assuring our customers that their assets are well-protected.

NEED FME? GET IN TOUCH TODAY?

Contact Ty-FlotA Heritage of Innovation & Partnership

Ty-Flot, founded in 1995 by the Moreau family, began as a pioneering force in the emerging nuclear market. Known for its strong partnerships within the industry, the company developed a reputation for innovation, holding patents for over 100 unique Foreign Material Exclusion (FME) solutions.

In 2018, Ty-Flot was acquired by Pure Safety Group and is now a part of Guardian family of brands. Today, Ty-Flot upholds its legacy of exceptional quality and service while broadening its impact across multiple industries.

The name Ty-Flot came from our very first patented product, the floating zip tie!

Our comprehensive range of FME products includes everything required to prevent debris contamination, from barriers, covers, caps, plugs, and tarps to customized solutions designed to protect even the most intricate systems.

By Failing to Prepare,

You are Preparing to Fail

If you’re going to be playing a competitive sport, you’ve got to practice if you want to do well. FME is similar because the work that you do will always be different but the preparation is mostly the same.

True preparation is in the details. An FME Ready Worker secures every item - including their tools, clothing, and gear - eliminating loose hazards with tethers, hook and loop fasteners, or tape. With clean shoe soles, empty pockets, and securely fastened papers, they reduce risks, protect the worksite, and uphold the highest operational standards.

What is the difference between

FOD control and FME?

The aviation industry refers to its debris control efforts as FOD Control or FOD Prevention, while the nuclear industry refers to the control as Foreign Material Exclusion. There are a few subtle differences in FOD Control and FME but the major concepts are the same.

Foreign Material

Exclusion Saves Costs

In FME you are paying to prevent future expenses but you are also getting great value as you pay. The reality is that most of the parts which are specially manufactured for foreign material exclusion are comparably priced to those items that are not fit for use in FME. For example: tinted plastic solutions are similar in cost to clear plastics. A lot of the items that are tailored for FME are also very long lasting, so the upfront cost is small and the return on the investment lasts a long time.

Industries

Nuclear

Nuclear Aerospace

Aerospace Food & Beverage

Food & Beverage Oil & Gas

Oil & Gas Automotive

Automotive Industrial Engineering

Industrial Engineering